How Do Polyaspartic SAPs Compare with Polyacrylic SAPs?

Discover how polyaspartic SAPs compare to traditional polyacrylic SAPs, offering high absorbency with plant-based chemistry and reduced environmental impact.

July 29, 2025

3 minutes

Hygiene

By Jim Robinson

A superabsorbent polymer (SAP) is a polymer that can absorb many times its weight of water-based fluids, including urine. This is why SAPs are a key ingredient in many disposable hygiene articles, such as diapers, period care products, and adult incontinence products. Historically, SAP’s are made from petroleum, but there is increasing market pressure to move away from this raw material.

This high level of absorbency comes from the polymer’s ability to form a network that traps liquid and holds it, allowing slow release over time. SAPs have helped revolutionize material science for personal care by reducing bulk, improving comfort, and providing better protection compared to older absorbent materials like cotton or paper pulp.

But polyaspartic SAPs are redefining hygiene product development by combining high performance with sustainable, plant-based chemistry.

Moving From Petroleum to Plant-Based Solutions

Currently, SAPs are almost exclusively made from polyacrylic acid, which is made from joining many segments of acrylic acid together into a polymer network. Polyacrylic acid is a chemical derived from petroleum.

While polyacrylic SAPs have proven effective and are widely used, the reliance on petroleum-based raw materials and the persistence of microplastics in the environment have raised questions about the long-term sustainability of this approach. As consumer expectations shift toward plant-based and biodegradable alternatives, the hygiene industry is seeking solutions that maintain performance while lowering environmental impact.

Now SAPs can be made from natural amino acids, thereby delivering a sustainably produced SAP. At Lygos, we make our polyaspartic acid from corn.

By sourcing raw materials from renewable agricultural inputs rather than fossil fuels, polyaspartic SAPs support a circular economy and give manufacturers a way to align their products with changing sustainability standards.

Lygos exemplifies this movement, combining plant-derived feedstocks with high-performance chemistry to create SAPs that work as hard as traditional options while breaking down cleanly at the end of their life cycle.

Comparing Structure & Performance

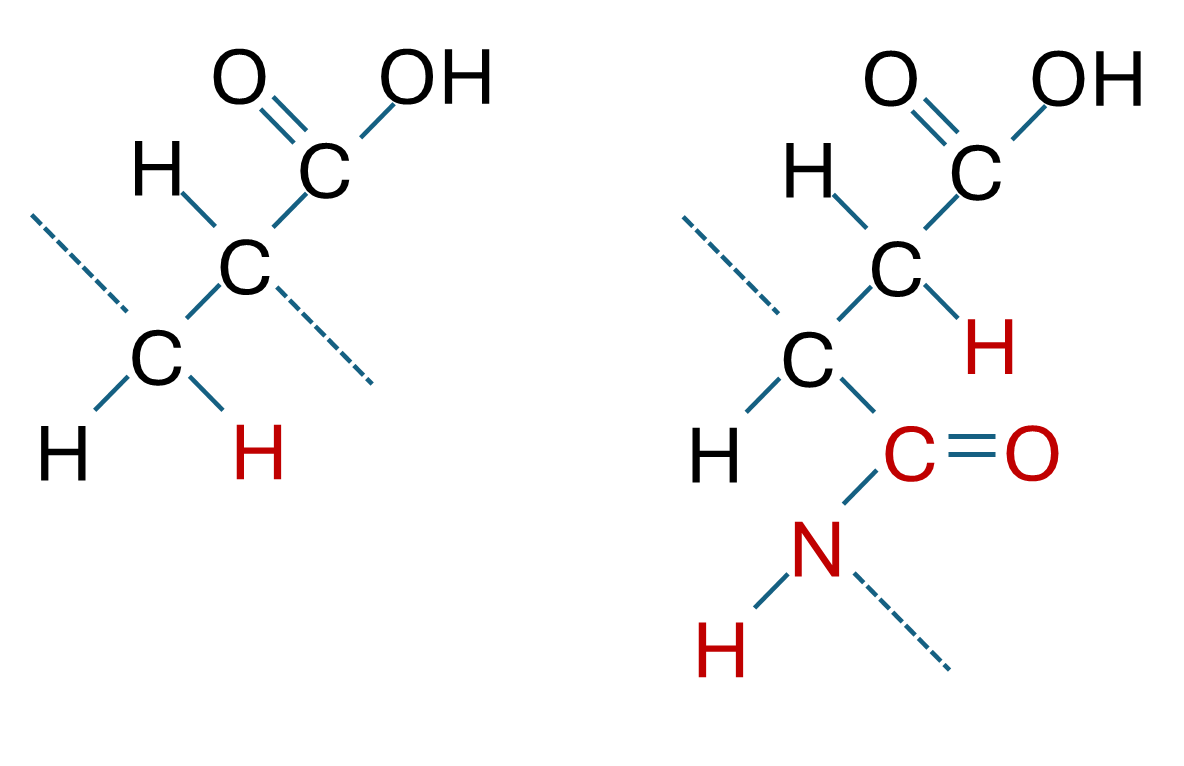

Looking at a single segment of the polymer, both types of SAP share part of their chemical structure, with the polyaspartic acid bringing different side groups. This subtle variation in structure creates additional binding sites that interact with water, enhancing the overall absorbency and retention.

Polyaspartic acid adds more oxygen and nitrogen to the backbone, and these sites are where the water interacts with the polymer to be bound. Polyaspartic acid gives good performance with the added benefits of:

- Plant-based raw material (no petroleum)

- Clean production

- Degradation into natural materials with no microplastics

These benefits can help companies start to future-proof their products against evolving regulations and consumer expectations. As sustainability becomes a defining factor in material selection, polyaspartic SAPs offer a forward-looking alternative that doesn’t compromise on quality or absorbency.

The Future of Sustainable SAPs

Polyacrylic SAPs have long been the standard, but they rely on non-renewable resources and contribute to environmental persistence. Polyaspartic SAPs allow cleaner production and natural degradation while maintaining their much-needed water-absorbing performance.

At Lygos, creating polyaspartic SAPs from corn demonstrates how innovation and environmental responsibility intersect. With renewable inputs and bio-based chemistry, these materials set a new benchmark for the future of SAPs, where performance and sustainability are equally achievable.

Want to learn more about SAPs and their role in hygiene industry progress? Get in touch with Lygos today.