Innovating for Excellence: How Lygos Optimized Soltellus™ for Superior Water Treatment

Partnering with Customers to Develop Impactful Solutions

July 15, 2024

2 minutes

Water Treatment

By Sierra Cotton

Download Free Water Treatment GuideAt Lygos, our commitment to innovation is driven by the needs and feedback of our customers. We continuously strive to enhance our products, ensuring they not only meet but exceed the expectations of the industries we serve. A prime example of this commitment is the development of Soltellus™ 2402L, a superior biodegradable scale inhibitor designed to enhance water treatment processes.

Listening to Customer Feedback

The journey began with Soltellus™ 2400L. Soltellus™ 2400L helps prevent scale formation across multiple applications, including cooling towers and membranes. However, through extensive customer feedback, we identified areas for enhancement that could lead to even greater performance and versatility.

Innovating for Superior Performance

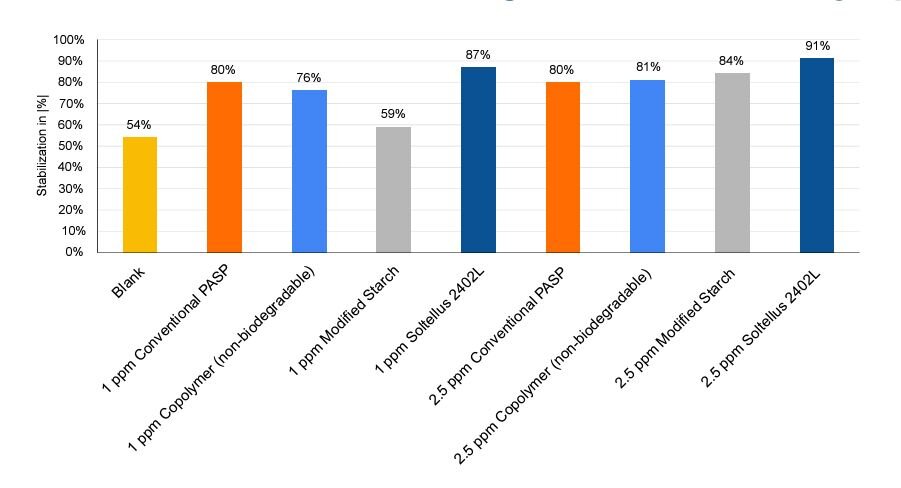

In response, our research and development team set out to refine the formula, resulting in Soltellus™ 2402L. This new product offers up to a 22% increase in performance compared to conventional commercial polyaspartate offerings, significantly reducing calcium carbonate and barium sulfate scale. The enhanced, non-toxic, biodegradable formula significantly improves operational efficiency and is a sustainable alternative to traditional anti-scalants.

Serving Diverse Applications Through Differentiation

The creation of Soltellus™ 2402L allowed us to explore product differentiation within the water treatment segment. By tailoring our solutions to better serve specific applications, we can provide targeted and effective products. While Soltellus™ 2400L is designed to tackle corrosion and scale in industrial cooling systems, Soltellus™ 2402L offers unparalleled protection and efficiency for water treatment processes in membrane filtration, manufacturing, mining, and oil and gas, safeguarding equipment, decreasing operational costs, and enhancing performance. This further demonstrates our ability to adapt and innovate based on customer needs.

Innovating for Excellence

Innovation is not just a buzzword at Lygos; it is a fundamental principle that guides our every endeavor. We understand that excellence is a continuous journey requiring constant refinement and improvement. Our drive to innovate stems from our desire to provide our customers with solutions that deliver exceptional results and maximum benefits. By developing close relationships with our partners, we gain valuable insights into how our enhanced performance drives results for customers. Soltellus™ 2402L is a shining example of how our commitment to innovation leads to the creation of products that set new industry standards.

A Commitment to Continuous Improvement

Soltellus™ 2402L is a testament to our commitment to listen to our customers, understand their challenges, and develop solutions that drive success and sustainability. Soltellus™ 2402L exemplifies our dedication to improving performance and expanding our product offerings to meet diverse industry needs.

Together, we are not just creating products; we are shaping the future of sustainable water treatment.